The Unicorn 5-200 is designed to enable more businesses and individuals to get into in-house manufacturing. As a gab-bridging machine, this is creating the opportunity for anyone previously limited by financials and space to get into compromise-free industrial grade 5-axis machining capabilities.

Including anyone who is currently limited by standard sized door openings!

Designed and built with a high number of tried and tested components from well-known and highly reputed manufacturers in the machine building industry, help to ensure high replacement part availability and maximum spindle up time throughout the life of the Unicorn 5-200.

Through it’s compactness and the optional add-ons and custom integrations, it can be set up for a wide range of applications such as educational institutions and in-house prototyping R&D.

For production purposes, it can be setup to excel in both High-Mix Low-Volume and Low-Mix High Volume in the medical, electrode making, jewelry, dental and other micromachining applications.

The Unicorn 5-200 empowers you with an extensive range of machining capabilities, enabling you to bring your vision to life with precision and finesse. This versatile machine excels across various materials, providing exceptional results for a wide array of industries and applications.

Whether you’re working with metals, plastics, composites, or advanced materials, the Unicorn 5-200 delivers consistent and reliable performance. With its cutting-edge technology and robust construction, it tackles the challenges posed by different materials, ensuring superior craftsmanship and accuracy in every project.

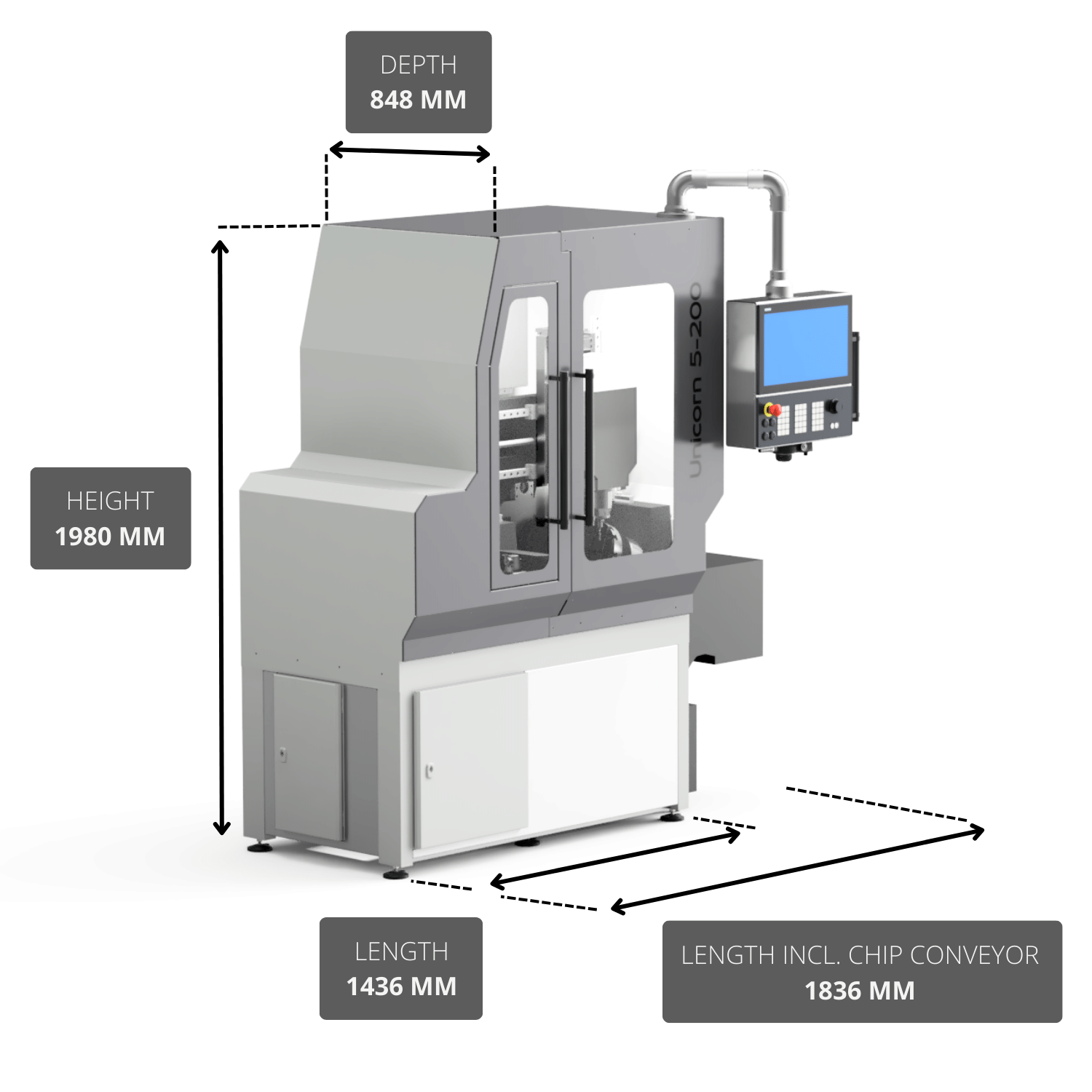

The first of it’s kind – A proper industrial grade universal 5-Axis milling machine which fits through a standard entrance door!

As it is lightweight and fits in most industrial elevators, this machine can also be installed on other floors than the ground level.

Machine is moveable with a standard pallet lifter.

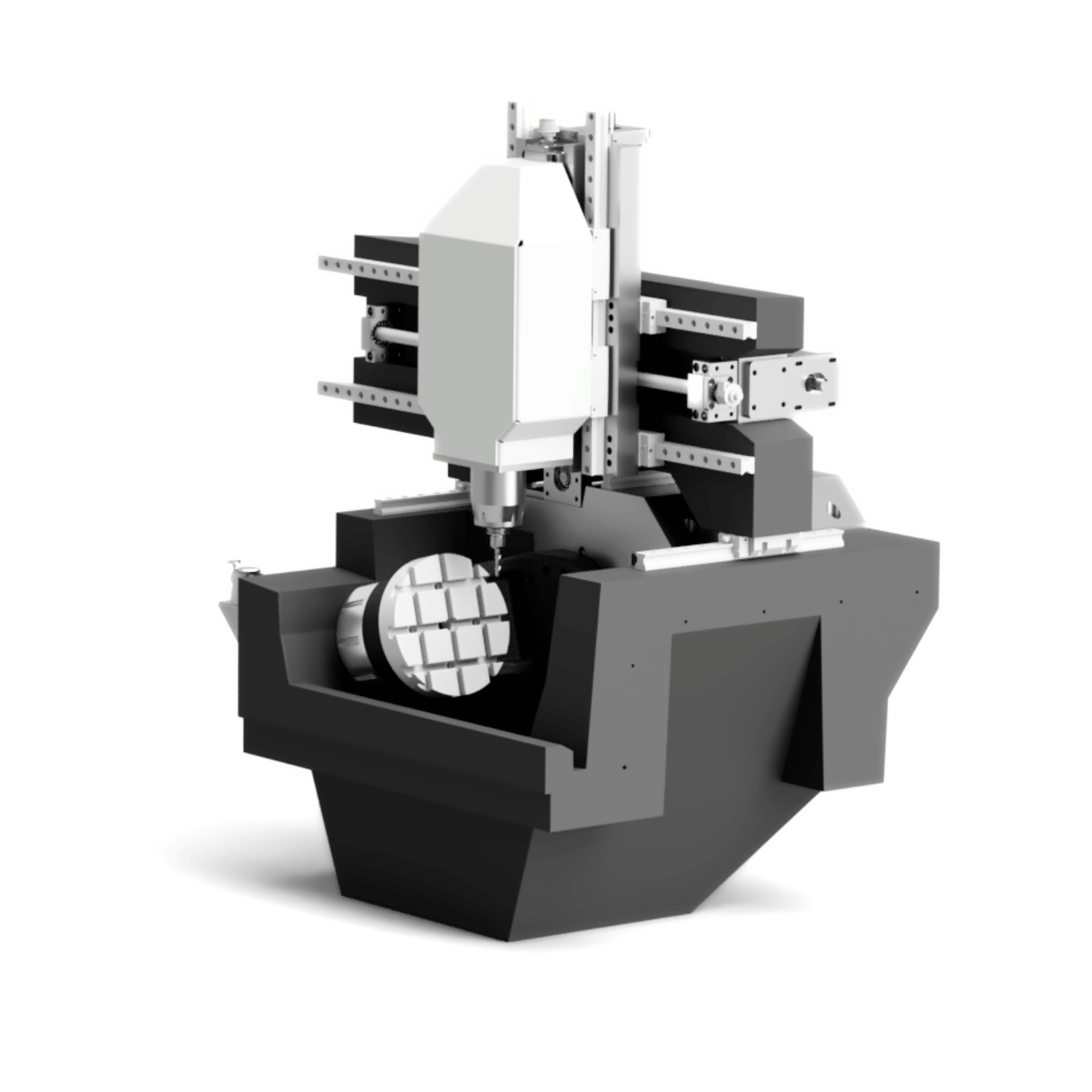

Experience the advantages of our mineral cast machine base frame and gantry beam, setting new standards in machining excellence.

Engineered with precision and durability in mind, these components offer a host of benefits:

Included Accessories

Key Features

19” Multi-Touch Panel Screen

Advanced 3D Simulation Capabilities

Simultaneous 5-Axis Machining (Multi-Channel High-Speed Machining)

Intelligent Dynamic Control (IDC) for Enhanced Precision and Surface Quality

Adaptive Feed Control (AFC) for Optimal Cutting Conditions

Real-Time Monitoring and Analysis of Machine Performance

Integrated Collision Avoidance System (3D Interference Check)

High-Speed Contouring Control for Fine Surface Finishing

Smart Interpolation Functions

Included Accessories

Portable Handheld Manual Pulse Generator

Key Features

19” Multi-Touch Panel Screen

Advanced 3D Simulation Capabilities

Simultaneous 5-Axis Machining (Multi-Channel High-Speed Machining)

Intelligent Dynamic Control (IDC) for Enhanced Precision and Surface Quality

Adaptive Feed Control (AFC) for Optimal Cutting Conditions

Real-Time Monitoring and Analysis of Machine Performance

Integrated Collision Avoidance System (3D Interference Check)

High-Speed Contouring Control for Fine Surface Finishing

Smart Interpolation Functions

Included Accessories

Portable Handheld Manual Pulse Generator